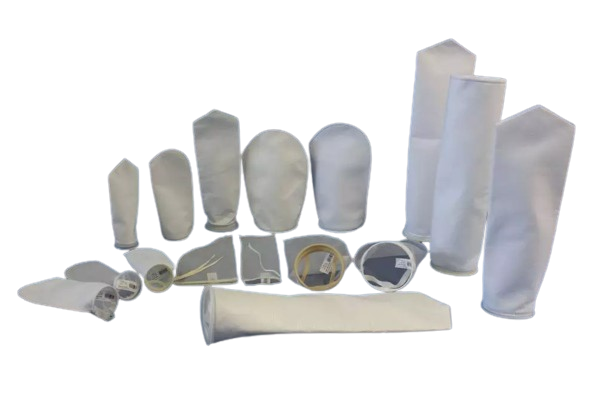

filter bags

Operation

- Filter bags are manufactured for optimum filtration

performance. They are carefully made from selected

media, according to the specifications of the process

industry; different types of media are used such as

nylon, polypropylene multi and mono filament

SALIENT FEATURES

- High Performance

- Wide Chemical Compatibility

- Good for viscid fluid filtration

- High dirt holding capacity

- Low on maintenance

Applications of Filter Bags

- Paints

- Oils

- Inks

- Pharmaceuticals

- High viscosity fluids

- Vegetable Oils

- Waste water Adhesives

Technical specifications

|

M.O.C |

|||||||||

|

Filtering media |

Polypropylene |

Polyester |

|||||||

|

Retainer |

Polypropylene |

Polyester |

|||||||

|

Configuration |

|||||||||

|

Bag Size(inch) |

Size1 (7Øx16.5L) |

Size 2 (7Øx32L) |

Size 3 (4Øx8L) |

Size 4 (4Øx14L) |

|||||

|

Micron Rating |

1, 5, 10, 25, 50, 100, 200 micron |

||||||||

|

Bag Type |

Fully Welded |

Welded side with sewn bottom |

|||||||

|

Retainer Type |

Polyform Seal (Polypropylene/Polyester) |

Custom Plastic Flange (Size-3/4) |

|||||||

|

Operating Conditions |

|||||||||

|

Max. Diff. Pressure |

1.72 kg/cm² ( 25 psi ) |

||||||||

|

Temperature Rating |

80 °C (Polypropylene Felt) |

135 °C (Polyester Felt) |

|||||||

|

Flow Rates |

18 m³/hr (Size-1) |

34 m³/hr (Size-2) |

6 m³/hr (Size-3) |

12 m³/hr (Size-4) |

|||||

other products